A Simple Guide to Conveyor Drive Types

Posted on

The drive is the part of the conveyor which powers the conveyor. It can refer to the motor or the assembly which mounts the motor to the conveyor (also known as the drive assembly). In this post we will be looking at the motor mount, or drive assembly.

Conveyor Drives

There a three main types of drive assemblies, they are, in the order of most to least common:

- End drive

- Center drive

- Internal drive

End Drive Conveyors

An end drive is exactly as it sounds, the drive assembly is located at one of the conveyor’s ends. The motor powers one of the end rollers on conveyor. Ideally, the drive is located at the discharge end of the conveyor, so that it is pulling the belt or chain over the pulley. In some instances, when the conveyor design has been reviewed and approved by a qualified engineer, the drive can be placed at the infeed – thus pushing versus pulling the belt or chain over the drive pulley. Either way, this drive style is also referred to as a “head drive” - as in the direction the product heads or toward the head of the conveyor.

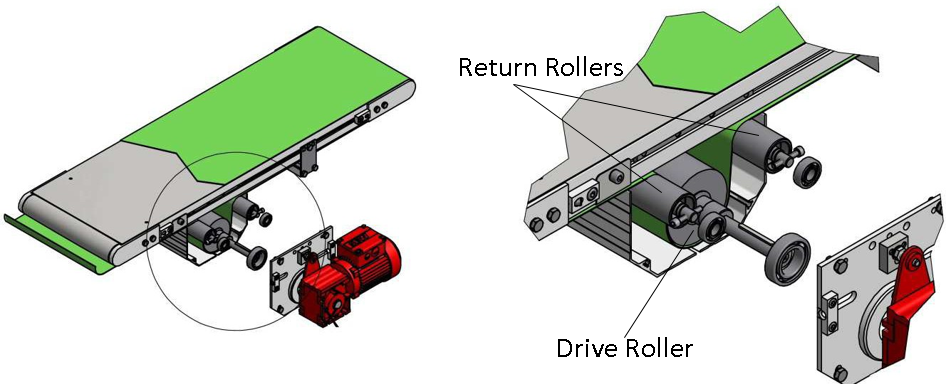

Center Drive Conveyors

As with an end drive, centers drives are as they sound – located along the center of the conveyor frame. That said this drive type can typically be mounted anywhere along the frame of the conveyor not just in the geometrical center of the conveyor. It should be noted that for it to be a center drive, the motor does not engage either of the conveyor’s end pulleys or rollers. These drives typically consist of three rollers, versus a single roller as used in end drive configurations. The three rollers consist of one drive roller, typically larger in diameter than the other rollers, and then two return rollers (also referred to as snub or idler rollers), located on either side of the drive roller. Because of the need for two idlers and a more complex design, center drives are more expensive than end drive. Center drives are also referred to as mid-mount drives.

Internal Drive Conveyors

The drive location in this example is "head left".

In both previous drive configurations, the motor is mounted externally to the conveyor; and engages with the drive pulley. However, with the 3rd drive assembly option; the internal drive drum motor, the motor inside, or internal to, the drive pulley. Meaning the drive pulley and the motor are one assembly or a single piece – the motor is housed within the pulley. This type of drive is most associated with belt conveyors, although it is possible to use this type of drive with a plastic modular belt conveyor. Internal drive conveyors can have the motorized pulley located at the end or in the center, however the end drive is far more common.

Drive Location

Aside from the drive being located at the end or “center” of a conveyor the drive can also be mounted on the left or the right side of the conveyor. Left and right are determined as if you were on, or riding the conveyor, left is your left and right is your right. For internal drives there is no drive location, pertaining to which side of the conveyor the motor is mounted on – yet it is important to select which side of the conveyor the power cord runs from.

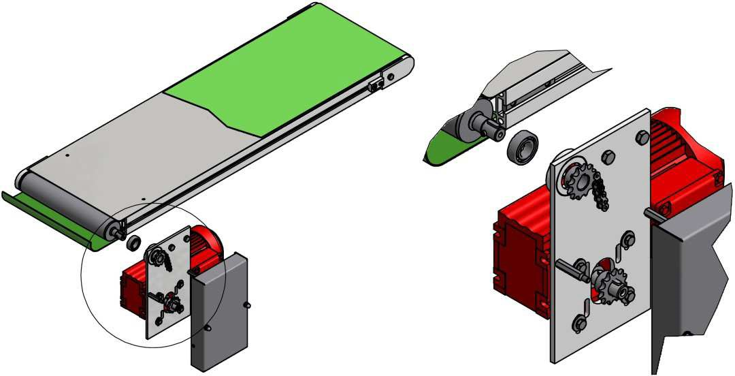

Direct or Indirect Drive

Further adding to the drive options available conveyors can either be direct drive or indirect drive. This refers to how the externally mounted motor engages with the conveyor. Note: This does not pertain to internal drive configurations.

Direct drives are the less complex of the two options and are thus typically the most economical choice. In a direct drive configuration, the motor directly powers the drive roller of the conveyor. With an indirect drive, the motor is mounted remotely of the drive pulley (often below, but it can be above or to the side of the conveyor) and a series of gears or sprockets and chain or timing belts transmits the power form the motor to the drive roller. These sprockets and chain/timing belt is called the drive train. This type of configuration can result in lost power between the motor and the drive pulley. However, it is very useful in that it allows for a change in rpm between the motor and the conveyor roller – thus making it possible to operate the conveyor at precise speeds or at speeds that could not otherwise be achieved.

Click Here to See and Download a Guide to mk's Different Drive Types

Choosing Your Conveyor Drive Type

When it comes to choosing the drive type for your conveyor the three main considerations are conveyor type, power requirements and space constraints. The conveyor type consideration being the single most important factor – as not all drive types are feasible for all conveyor types. The amount of power required for the conveyor type may be a restricting factor in the type of drive that can be used. And the same goes for the available space. If there is not room for a motor at the discharge of the conveyor, and the application is such that it cannot be placed at the infeed, then either a center drive or an internal drive is necessary. But going back to how the conveyor type affects this decision, the type of drive that can be used could affect this.

Working with a conveyor manufacturer like mk North America makes this decision easier. mk’s highly trained and dedicated sales staff will work with you from concept through delivery and beyond to ensure that your conveyor is the right fit and function for your application. Contact mk North America today to get started on your next project - you can use the form below or call (860) 769-5500 ext 3000.