Problem Defined

Conveying Batteries in a Vertical Position

An electrical automotive manufacturer needed a conveyor system developed for which not only would transport their product, round batteries, but also assist in cleaning the batteries, visually inspecting and electrically testing each battery. Batteries that did not pass the various inspections and tests would need to be rejected from the conveyor line. The batteries, 46 mm diameter and varying in heights from 80 to 120 mm, needed to remain in the upright position at all times and could not be conveyed on a pallet. Additionally, there was a 2,500 mm elevation difference between where the battery were introduced into the production line and the where they needed to exit the conveyor and into the robotic assembly cell. A high throughput and process reliability were also paramount to this project being a success.

mk North America's Custom Solution

Providing Solutions for Battery Conveyors

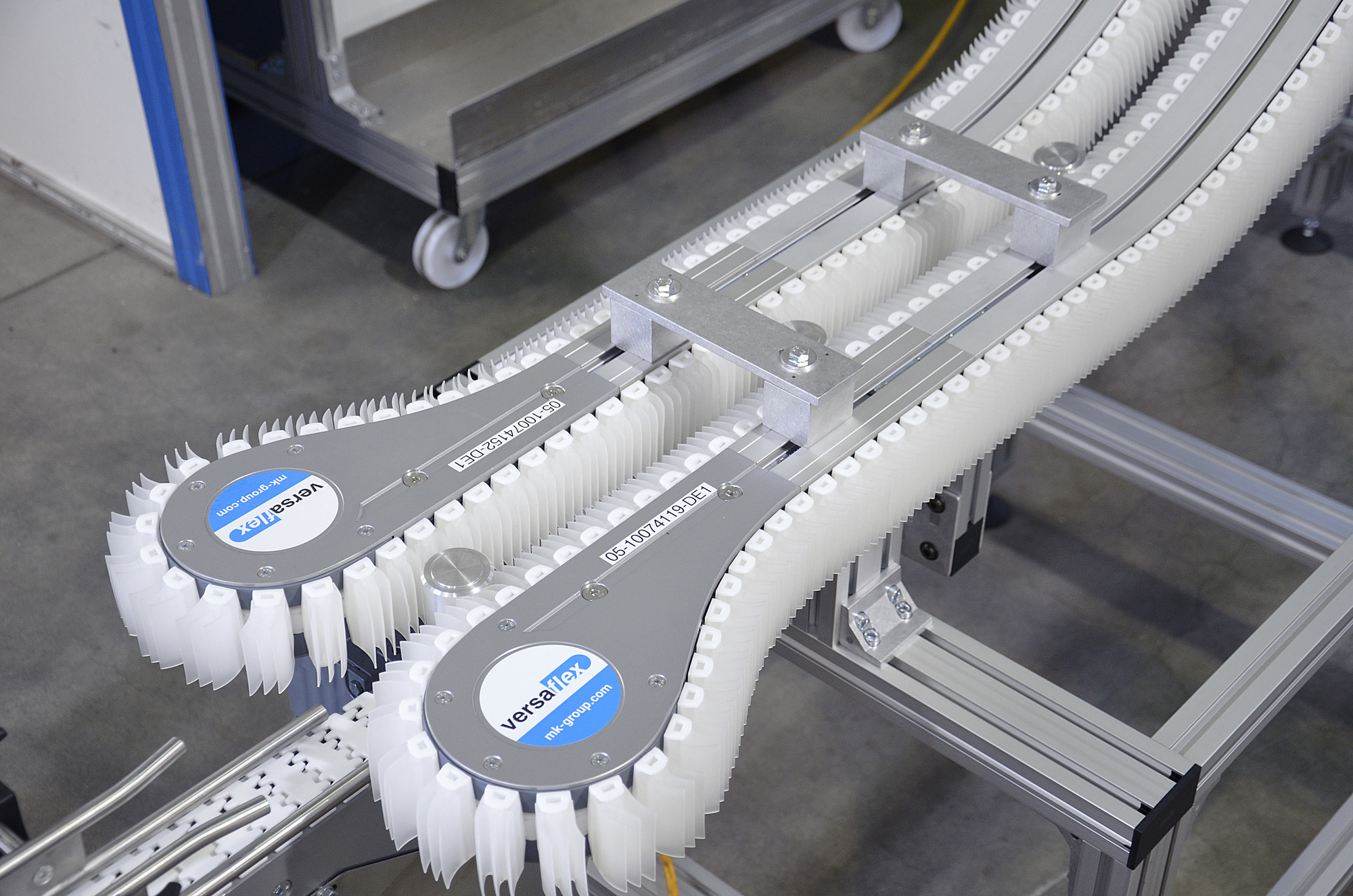

mk's VersaFlex conveyor system, in particular model A06, is ideal for transporting these batteries in the upright position. For the horizontal conveyor sections, side rails were used to hold the battery into the upright position. In order to move the product between elevations, as well as expose the bottom of the battery for the various inspections and tests a gripper conveyor (also known as a wedge conveyor) was utilized. The gripper conveyor consisted of two VersaFlex A06 wedge conveyors. The cycle time on this project was 0.1 seconds per unit or a throughput of 600 battery cells per minute. This equated to a conveyor speed of approximately 98 fpm. The total conveyor length was approximately 20 meters.

Customer Benefits

- Accomplishing all material handling and inspection goals with a conveyor solution from a single supplier.

- A very fast, smooth and safe means of transporting their product.

- The ability to conveyor multiple different height products on one conveyor.

- The ability to access the bottom of the battery, while the battery remained in the upright position, for visual inspection and scanning

- A conveyor system with a modular approach that allows for future line reconfiguration and changes.

Related Products