The Challenge: Problem Defined

American Feeding Systems, a leading company specializing in industrial vibratory feeders, required a custom conveyor solution for a new production process involving rubber tubes. The project demanded a conveyor system that could efficiently transport tubes of varying sizes through a hopper system and up an incline to a designated unloading area. The tubes, with diameters of 9.5 mm and widths of 146 mm and 279 mm, needed precise handling to prevent damage and ensure smooth operation throughout the process.

The Solution

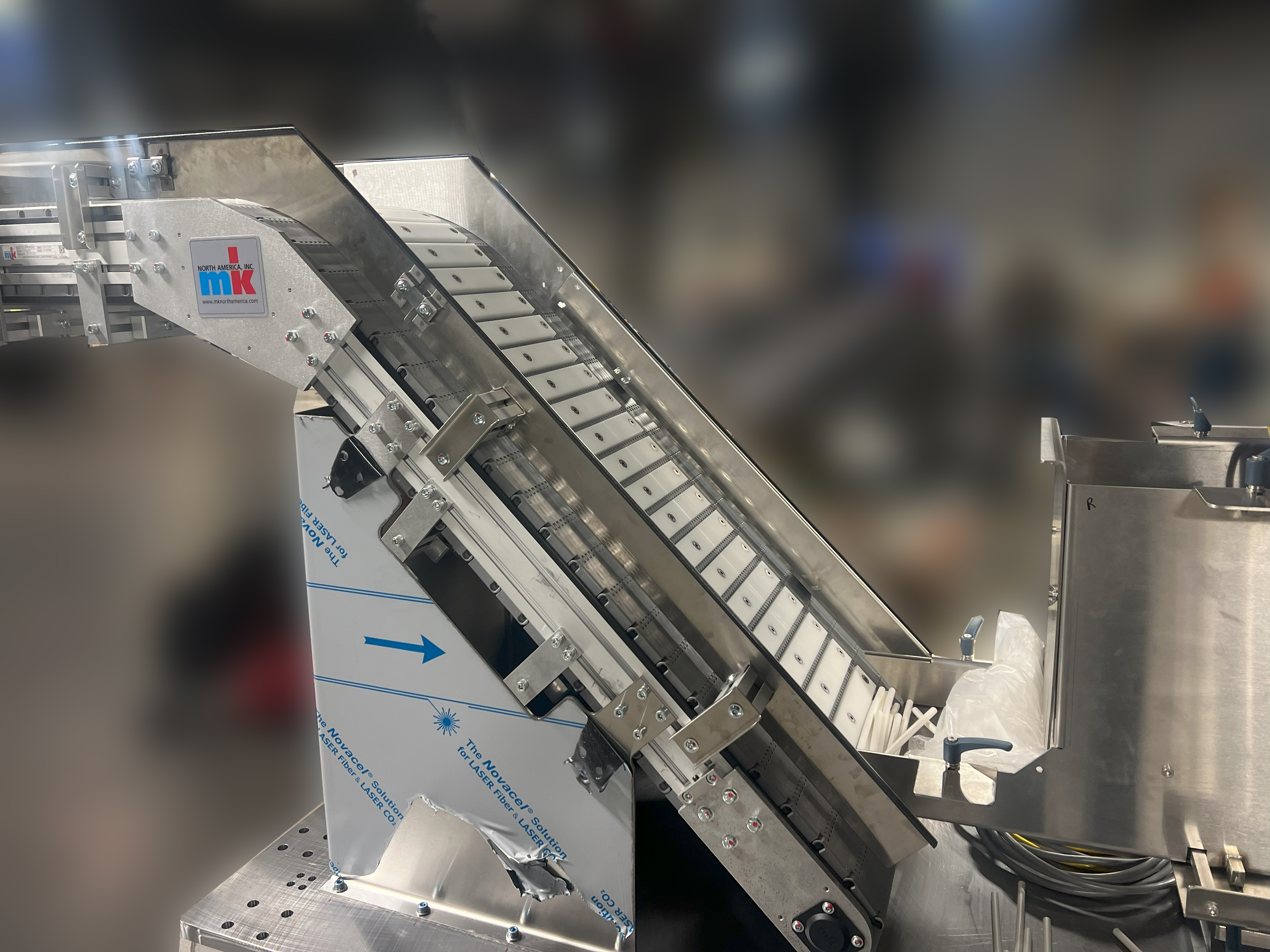

American Feeding Systems partnered with mk North America to design and build a custom incline-to-horizontal plastic modular conveyor using mk’s KFM-P 2040 series. This versatile conveyor system was tailored to the unique needs of the client, focusing on durability, precise transport, and ease of integration.

American Feeding Systems partnered with mk North America to design and build a custom incline-to-horizontal plastic modular conveyor using mk’s KFM-P 2040 series. This versatile conveyor system was tailored to the unique needs of the client, focusing on durability, precise transport, and ease of integration.

Key features of the system included:

- The incline section measured approximately 990 mm, and the horizontal section measured approximately 615 mm, with an incline angle of 45°.

- The system’s usable width was 400 mm, and the infeed and discharge heights were set at 937 mm and 1,700 mm, respectively.

- Designed to handle payloads up to 50 lbs. at 30 fpm, non-accumulating.

- Custom polypropylene flat-top belt; which the customer bolted flat fixture.

- And fixed, removable side rails, providing additional support and guidance for the transported tubes.

The KFM-P 2040 conveyor’s modular design, built with a t-slot aluminum extrusion frame, provided both durability and flexibility, making it the perfect solution for transporting rubber tubes. mk North America and American Feeding Systems worked closely together to create custom cleats and a belt insert pattern that ensured each tube was delivered one at a time. This design prevented tubes from stacking or wedging in the pockets, while also spacing them appropriately for an upstream process.

Because of mk's modular design, the conveyor easily integrated into American Feeding Systems' existing setup, ensuring a smooth flow through the hopper system.

Results: Benefits to the Customer

The custom conveyor system from mk North America successfully met all of American Feeding Systems’ expectations. The system allowed for the efficient, precise transport of rubber tubes, significantly improving the throughput and reducing downtime in their production line. With mk North America's solution, the client saw notable improvements in handling efficiency, ensuring that tubes were consistently conveyed and unloaded without issue.

The client also appreciated the robust construction and ease of installation provided by mk’s custom design; as they were providing the supports, chutes and system integration. The system was delivered within the 7-week lead time and was shipped in sections for straightforward assembly at the customer’s facility. Additionally, the inclusion of SEW inverter-duty gearmotors and variable frequency drives ensured long-term performance and flexibility in speed control.

The client also appreciated the robust construction and ease of installation provided by mk’s custom design; as they were providing the supports, chutes and system integration. The system was delivered within the 7-week lead time and was shipped in sections for straightforward assembly at the customer’s facility. Additionally, the inclusion of SEW inverter-duty gearmotors and variable frequency drives ensured long-term performance and flexibility in speed control.

Conclusion

mk North America’s customized KFM-P 2040 conveyor system provided American Feeding Systems with an efficient, reliable solution for their rubber tube handling process. The successful partnership between the two companies underscores mk’s commitment to delivering tailor-made solutions that improve production efficiency and meet specific application requirements.

If you’re facing a unique challenge in your production process, contact mk North America today to learn how we can help you optimize efficiency and achieve your manufacturing goals.

mk Products Featured