Plastic Modular Belt Conveyor

Request a Quote

Product Information for Plastic Modular Belt Conveyor

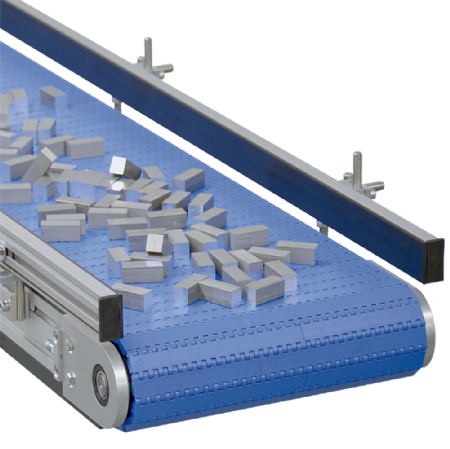

The MBF-P 2040 is a plastic modular belt conveyor, which features a streamlined conveyor design.

What distinguishes these conveyors, plastic modular belts, from standard flat belt conveyors is their high load capacities, even at narrow belt widths. The plastic modular belt is positively driven, which reduces tracking difficulties (in particular situations).

Because the plastic belt is built in interlocking segments it is possible to replace a damaged portion of belt without replacing the entire conveyor belt, thus resulting in cost and time savings. Plastic modular belts are also (typically) resistant to wear, making it ideal for food industry applications and those involving high temperatures or caustic chemicals. mk's MBF-P 2040, plastic modular belt conveyor's high load capacity also makes it useful for heavy material handling, such as in automotive or and metal working industries.

Plastic Modular Belt Conveyor Features:

- Frame: 80 mm deep aluminum profile frame

- Width: 80 mm up to 3,000 mm

- Length: 400 mm to 10,000 mm

- Load: Up to 1,000 lbs.

- Speed: Up to 200 fpm

- Constant or Variable speed

- Voltage: All standard US, Mexico and Canadian voltages

- Belting: Plastic modular belt, flat top, flush grid, and textured; plus options for cleats and sidewalls

- Accessories: Compatible with all mk side rails and supports

Catalogs, Resources & Downloads for Plastic Modular Belt Conveyor

Technical Specifications for Plastic Modular Belt Conveyor

- Constructed using our mk 2040 series structural profile

- 80 mm tall anodized aluminum frame

- Dual t-slots along the length of the frame, per side

- UHMW-PE slider bed

- UHMW-PE underside belt support

- Maintenance-free dual-sealed ball bearings

- Wide variety of belting materials to handle diverse customer applications

- Wide variety of belting styles – open top to flat top to textured surfaces

- Lateral cleats and side walls available for the belt

- Positively driven via a sprocketed drive pulley

- Modular belting benefits

- Quick and easy change of damaged belt sections without the need to replace the entire belt

- No need to disassemble the conveyor or remove it from its stands

- Allows for the ability to have the conveyor width greater than the length

- Compatible with all mk 40 system profiles and components and most mk 50 system profiles and components

- Large selection of conveyor accessories

Product Options for Plastic Modular Belt Conveyor

Plastic Modular Belt Conveyor Options Include:

- Covers

- Encoders

- Lane dividers

- Product escapements

- Specialty belt materials

- Infeed and discharge chutes

- Side tables and workstations

- Drip pan and product catch pans

- Custom motor and control options

Plastic Modular Belt Conveyor Engineered Solution Options Include:

- Accumulation and bi-flow tables

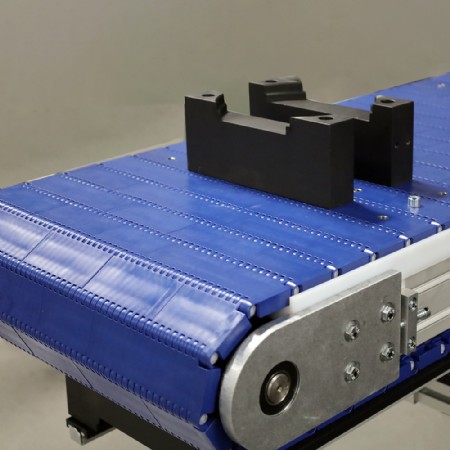

- Attachment style plastic modular belting

- Side running conveyors