Flat Belt Conveyors

Flat Belt Conveyor Common Uses:

- Assembly

- Elevation Changes

- Material Handling

- Packaging

- Piece Handling

- Plastics

- Printing Applications

- Sorting

- Transfers

mk North America offers the widest variety of aluminum frame flat belt conveyors in the industry. With 6 different platforms, we're able to accommodate the best fit for your application regardless of your material handling needs. See our lineup of products below.

Types of Flat Belt Conveyor Systems

- GUF-P 2000 - our most popular and versatile model

- GUF-P 2041 - our most heavy-duty belt conveyor

- GUF-P MINI - our smallest frame flat belt conveyor system

- KFG-P 2000 - z-frame or gooseneck style belt conveyor

- KGF-P 2040 - curve belt conveyor

Constructed out of our mk aluminum extrusion, our mk flat belt conveyors are fully compatible with all of the other factory equipment modules we offer. This modular design allows for you to quickly and easily add to and modify your production line. Belt conveyor systems from mk are the factory workhorse, delivering you quality, dependable and reliable conveyance shift after shift.

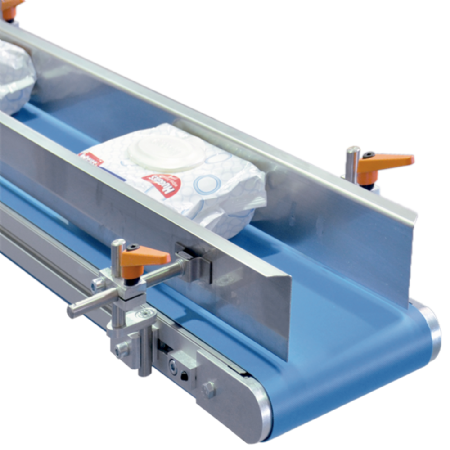

GUF-P 2000

Our most versatile and popular belt conveyor

- Max Width: 800 mm

- Load: Up to 300 lbs.

- Speed: Up to 500 fpm

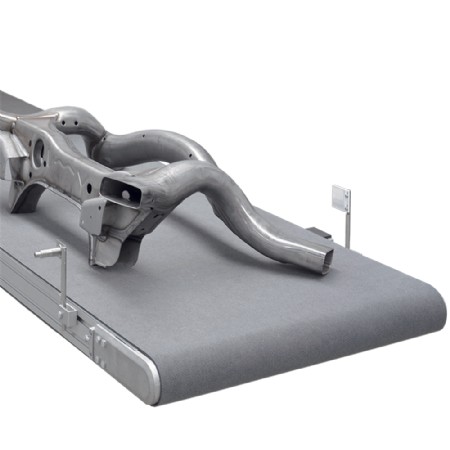

GUF-P 2041

Our most heavy-duty and widest width belt conveyor

- Max Width: 1,200 mm

- Load: Up to 500 lbs.

- Speed: Up to 500 fpm

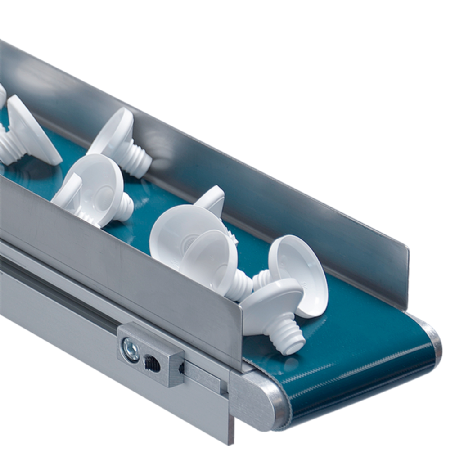

GUF-P MINI

Our lowest profile belt conveyor ideal for small spaces

- Max Width: 150 mm

- Load: Up to 100 lbs.

- Speed: Up to 200 fpm

KFG-P 2000

A z-frame belt conveyor for elevation changes

- Max Width: 700 mm

- Load: Up to 150 lbs.

- Speed: Up to 75 fpm

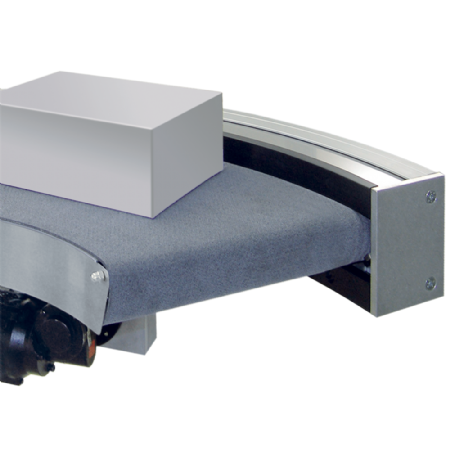

KGF-P 2040

A curve belt conveyor featuring a space saving design

- Max Width: 600 mm

- Load: Up to 75 lbs.

- Speed: Up to 75 fpm

More Information about mk Flat Belt Conveyors

Belt conveyors consist of two or more pulleys with a continuous loop of fabric, linked plastic segments, or other belting around them. When the pulleys are powered, the belt moves forward along with any product or material on top. Belt conveyors are extremely versatile economical tools for moving products in a variety of industrial applications and contexts.

Finding the right belt conveyor manufacturer for your needs can be a daunting task, but mk North America’s combination of precision engineering, flexibility, and support makes us the belt conveyor supplier of choice for companies across the globe.

In addition to standard flat belt conveyor systems, mk offers numerous other belt conveyor options tailored to specific applications:

- Low-Profile Belt Conveyors – Low-profile conveyors like mk’s GUF-P MINI are ideal for small parts handling, slug removal, and more.

- Incline/Decline Belt Conveyors – Belt conveyors systems engineered with steep or gradual inclines are important for applications involving elevation changes, hoppers, bowl feeders, and more. Inclined conveyors can also provide employees with essential ergonomic support.

- Curved Belt Conveyors – Belt conveyors with curved frames or segments are useful for engineering space-saving designs, making tight transfers, and more. mk offers curved belt conveyors at angles as much as 45, 90, or 180 degrees.

Numerous styles of belts are also available, including smooth, tacky, textured, anti-static, food grade, and cleated belt options.

Need a customized flat belt conveyor?

Contact us online or call (860) 769-5500. Our experienced sales staff will be happy to assist you.