Modular Plastic Belt Conveyors

Modular Plastic Belt Conveyor

Common Uses

- Automated and Manual Assembly

- Cooling, Curing, and Heating

- Curve Conveying

- Incline Conveying

- Machine Part Handling

- Packaging

- Piece Handling

- Sortation

Modular plastic belt conveyors are ideal for high load applications, even at narrow belt widths. High speeds, positive tracking, accumulation, drainage, or air flow are additional reasons to use this type of conveyor.

Benefits of Modular Plastic Belt Conveyors

Modular plastic belt conveyors utilize hinged, interlocking plastic segments to form the belt instead of the more conventional flat belts. This allows for a segment of damaged belt to be replaced, thus reducing the amount of down time and belt replacement costs. Plastic modular belt conveyors increase production time, decrease downtime and expenses.

mk North America can design and manufacture modular plastic belt conveyors customized to our customers’ specific needs. Whether you’re a general manufacturer or have unique industry-specific challenges, mk can design and build a system that will work for you for years to come.

KFM-P 2040

A plastic modular belt conveyor for inclining conveying

- Max Width: 1,000 mm

- Load: Up to 300 lbs.

- Speed: Up to 100 fpm

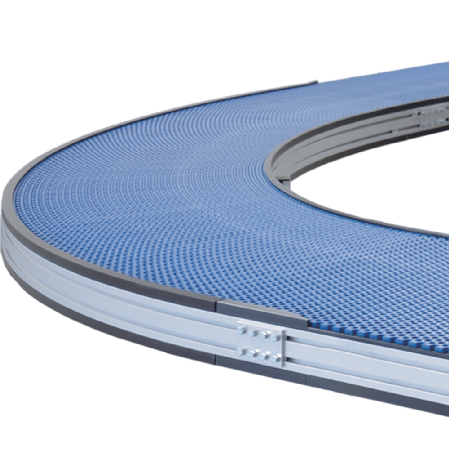

KMF-P 2040

A plastic modular belt conveyor for transporting around corners

- Max Width: 1,005 mm

- Load: Up to 330 lbs.

- Speed: Up to 100 fpm

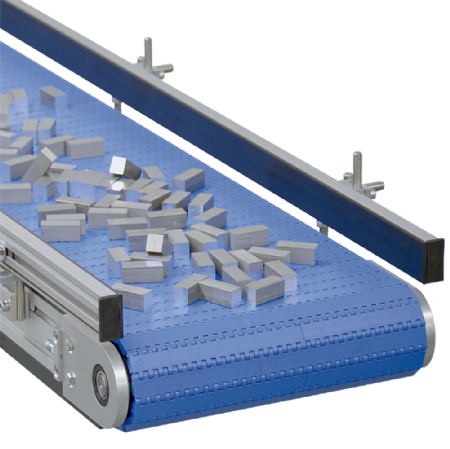

MBF-P 2040

A straight running plastic modular belt conveyor

- Max Width: 3,000 mm

- Load: Up to 1,000 lbs.

- Speed: Up to 200 fpm

Need help designing a modular conveyor to your specifications?

Contact us online or call (860) 769-5500. Our experienced sales staff will be happy to assist you.