What is Extruded Aluminum, and What Are the Benefits?

Posted on

What’s Extrusion?

Extrusion is a process by which material is pushed or pulled through a cast or die of a specific cross-sectional pattern to create a uniform profile.

Almost any substance can be the subject of an extrusion process – from pasta dough to titanium – but one of the most common materials is aluminum. Extruded aluminum is a widely-used material across a variety of applications, and with good reason.

Benefits of Building with Aluminum

Aluminum is naturally rust and corrosion-resistant, making it ideal for mining operations, military structures, and anything likely to be exposed to the elements. Strong for its weight, aluminum is also a good choice for framing load-bearing structures, as well as cars, trucks, planes, and boats. As if that’s not enough, it’s also highly conductive, nonmagnetic, non-combustible, and completely recyclable. If you’ve ever encountered stairs, gangways, docks, railings, panels, or pallets that looked like they were made out of aluminum; there’s a good chance they were extruded aluminum.

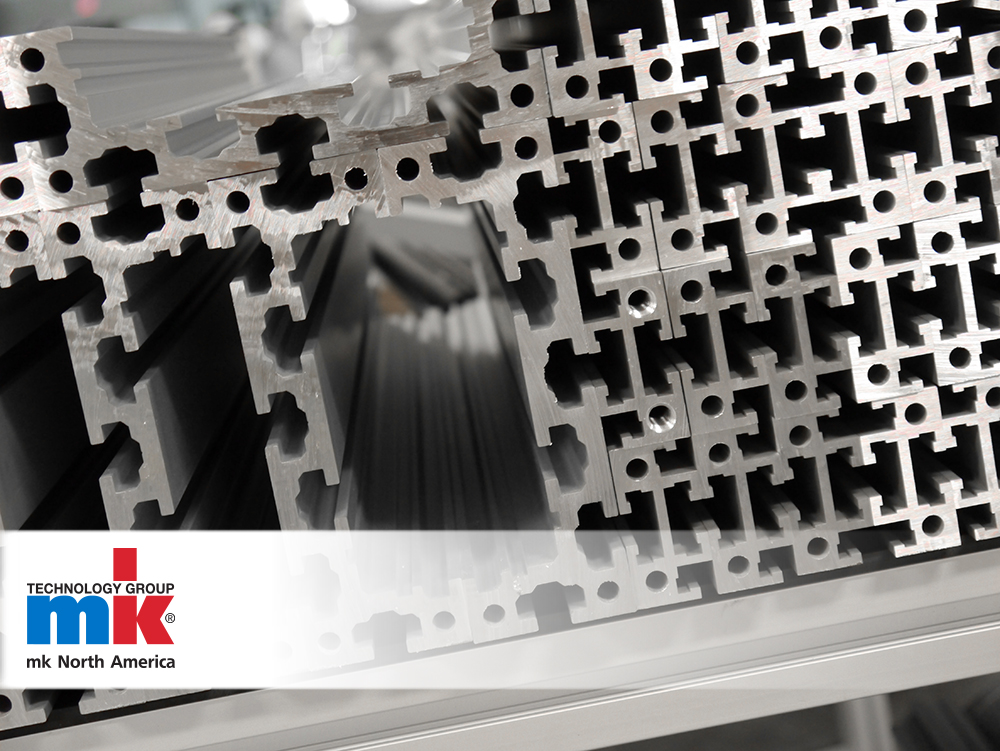

Benefits of T-Slot Profiles

For all its versatility, when someone says “aluminum extrusions,” in all likelihood they mean t-slot profiles. The cross-sectional shape of these aluminum profiles features a T-shaped track made of negative space, which is used to secure individual length to one another with specialized t-slot nuts and bolts.

This offers a distinct advantage over alternatives such as welded steel – namely ease and cost-effectiveness. T-slot framing also allows for flexibility of design. With welded or other more permanent framing options, modifications can be difficult or downright impossible. Removing or replacing parts in a t-slot system to account for a design change or revision is relatively easy by comparison.

mk Extrusions

mk offers extruded aluminum profile with t-slots in four different series. The different series and their features are highlighted below.

25 Series – Based on a 25 mm square with a 6 mm t-slot

- 17 different profiles

- Shapes include quarter round, hexagon and octagon

- Largest shape is 20 x 160 mm

- Primarily used for light duty frames and prototypes

40 Series – Based on a 40 mm square with a 10 mm t-slot

- Over 40 different profiles

- Shapes include angular pieces, rounds and quarter rounds, telescopic shapes, ovals and platform treads

- Many shapes also have light, standard and heavy-duty versions

- Also includes flat finish (or closed t-slot) profiles ideal for clean rooms

- Largest shape is 80 x 160 mm

- Primarily used for workstations, carts and guarding

50 Series – Based on a 50 mm square with a 10 mm t-slot

- Based on a 50 mm square

- Features a 10 mm t-slot

- 11 different profiles

- Largest shape is 50 x 200 mm

- The structural base for many conveyors, including the GUF-P 2000 our most popular model

- Also used in higher load cart and workstation applications

60 Series – Based on a 60 mm square with a 14 mm t-slot

- 4 different profiles

- Includes a 180 x 60 mm and 120 x 120 mm size

- Typically used in high load applications such as machine bases and cantilevered gantries

If you’re in the market for aluminum framing, mk North America offers custom framing systems for factory equipment, linear motion machines, robot guarding, machine guarding, conveyor systems, and more.

Contact us today to learn more.