Stainless Steel Conveyor System Solutions for the Food Packaging Industry

Posted on

As incomes across the developing world rise, the demand for pre-packaged foods on the world market is increasing many-fold and putting greater strain on existing packaging automation systems. While the benefits of packaged foods for consumers and manufacturers are well documented (increased shelf-life, lower costs, improved hygiene, et cetera), the challenges of increasing global demand are still emerging as food manufacturers struggle to adapt.

Among five areas of focus for the future of the industry singled out by The California Institute of Food and Agricultural Research at the University of California, Davis are, “optimization of equipment and utilities” and “advanced automation and control methods.” These stand out as areas where modern, custom-engineered conveyor systems are necessary solutions. Conveyor systems are the backbone of any food production line, making proper design, manufacture, and system integration crucial to increasing output while keeping costs competitive.

A worldwide leader in the design and manufacturing of custom conveyor systems across industries, mk North America has a number of conveying solutions ideal for those in the business of food production and packaging.

mk's CleanMove Stainless Steel Conveyors

mk’s CleanMove line of stainless steel conveyor systems is one such solution, specifically designed to meet many of the challenges inherent to food production. Hygiene and sanitation are two such difficulties. The CleanMove systems’ stainless steel construction makes them capable of high pressure washdown of up to 1,500 PSI, with other special features to accommodate the rigors of the packaging industry as well.

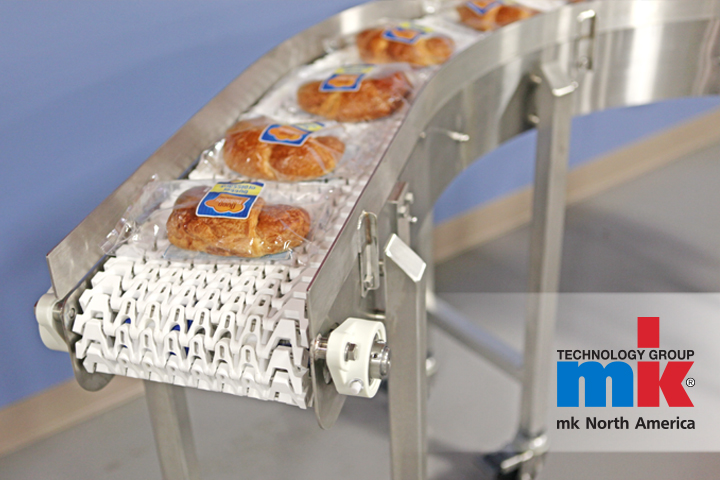

Modern food production and packaging also demands flexibility and scalability of size and function; a single production line might have thousands of feet of conveyed transport performing functions as diverse as washing, indexing, diverting, accumulating, and staging for human workers. With three design platforms and conveyors ranging from simple steel-frame belt conveyors to cleated conveyors, gooseneck conveyors, z-frame conveyors, curved conveyors, and more the CleanMove line of stainless steel systems can meet every need.

The CRM-200 is made to take finished goods around corners with curved design and FDA-approved plastic modular belt, making it perfect for transport between different stages of production. The same is true of the CIM-400, which is well-suited for moving product between levels and elevations to maximize floor space. These and other conveyors facilitate tight transfers required by many food production processes.

Whatever the size and technical requirements of your production line, mk North America is capable of providing you with conveyor systems to meet your every need. In addition to our CleanMove stainless steel conveyors, we can also work with you to create fully customized solutions for any production or packaging need. Contact us using the form below or by calling (860) 769-5500 to get started.