Smart Manufacturing: Backlit Conveyors Help Optimize Operations

Posted on

Today’s factories are getting smarter and more efficient than ever before. Thanks to emerging connected technologies and automation, smoother processes and greater accuracy are possible.

Collaborative robots are being used in these work environments to assist with intensive tasks and not only lessen dangers for human workers, but also to help businesses improve their profit margins.

This hot topic of “Industry 4.0” continues today and new updates in the manufacturing world are allowing for constant innovation.

Technologies like machine vision and the use of backlit conveyors are just some of ways operations are being optimized.

In this post we’ll look exclusively at the ways backlit conveyors are being applied in factories and how the technology is helping organizations to succeed with the smart manufacturing model.

What are Backlit Conveyors?

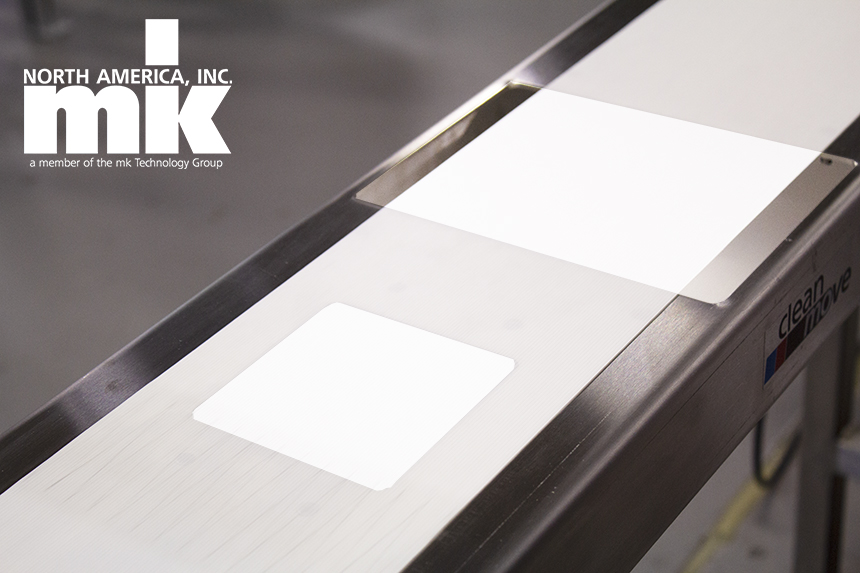

First, a refresher. Backlit conveyors are used as a way to provide optimal contrast between the item on the belt and the conveyor belt itself. To do so, a light panel is added to the frame of the conveyor that emits light through a translucent belt, which then illuminates the area under the light panel. This creates a clear optical view which has many benefits.

Applications & Benefits

Backlit conveyors certainly help with inspection processes - since the optical view of the product is greatly improved. A better, clearer view of the product increases accuracy and quality output for both manual and automated inspections. Departments like labeling, assembly, quality control, and more can all benefit from the ability to more clearly see the items in front of them.

Backlit conveyors also play an important role in machine vision as the clear view of the items makes it easier for even robots to process necessary information.

Machine vision is increasingly being used in robotic picking units and a number of other Industry 4.0 applications.

Envisioning the Future

As we progress into the future, there will continue to be more use of emerging technologies in manufacturing facilities. The incorporation of smart devices that can handle varied and specific tasks such as methods to move heavier loads, perform intricate handling with success, and even ways to improve energy efficiency are some of the examples. The challenges that conveyors are solving is growing into the future and it’s certainly an exciting time.

Choose mk North America

mk's standard flat belt conveyors are offered in both aluminum and stainless steel conveyor platforms and can include back-lit features by adding an LED light panel into the conveyor frame. If your operation is looking for better solutions and a move into the future of manufacturing, let mk help you get there!