Roller Chain vs. Accumulation Roller Chain Conveyor

Posted on

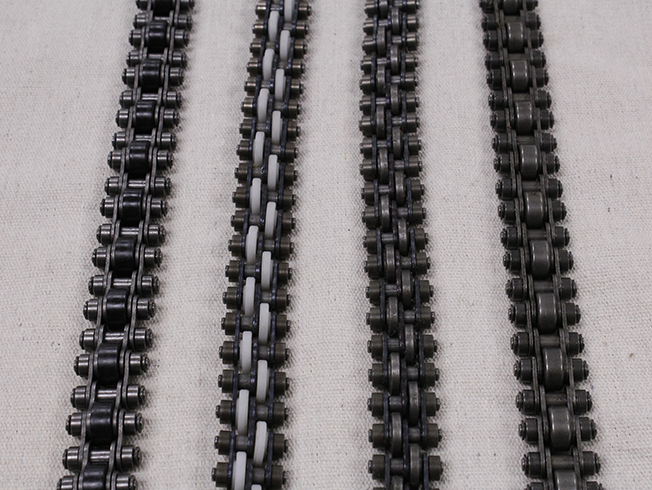

Accumulating Roller Chain (from left to right): Inline – Plastic Rollers, Staggered – Plastic Rollers, Staggered – Steel Rollers, Inline – Steel Rollers

Conveyors are the workhorse of the manufacturing industry. Often the most critical piece of equipment in the factory; they need to transport product while offering numerous safety and efficiency benefits.

In this post, we’ll look at a few of the distinguishing differences between roller chain conveyors and those designed to accumulate, and why choosing the optimal conveyor platform (for your application) is key.

Roller Chain Conveyor Uses

Roller Chain Conveyors are typically referred to as “chain conveyors.” These conveyors generally move at a consistent speed, and do not utilize stops or other mechanical devices to regulate the product flow. Chain conveyors are important in facilities that must transport heavy, oversized materials from one place to another. Because they work well for this basic function of moving the product along, chain conveyors are a proven option in these types of environments.

A great example for using a chain conveyor is moving car parts or industrial pieces where human workers would be injured or incapable of lifting the items to their destination. In addition to heavy-duty conveying, roller chain conveyors are also ideal in harsh environments where abrasives are used or sharp products are being conveyed.

Benefits of Accumulation Roller Chain

When it is necessary to precisely control product flow and allow for product staging, accumulation or storage; accumulating roller chain conveyors are the best choice. Like standard chain conveyors, these systems have chain as the conveying medium; however they use a different type of chain. Accumulating roller chain contains free-spinning wheels, or rollers. These rollers provide a nearly zero-backpressure conveying surface; making these conveyors excellent for accumulating or storing materials. The rollers in combination with the smooth accumulating surface reduce the noise output while the conveyor is running.

Options for accumulating roller chain include choosing from plastic or steel rollers, and having them inline or staggered depending on the product being carried. Pitch can also assist with moving heavier loads. While the standard chain has a ½” pitch, with a heavy-duty ¾” pitch option, it’s possible to move loads up to 3,500 pounds if needed.

Unlike the standard roller chains we discussed in the previous section, this set-up is a top solution for conveying even the most difficult to move products. When using these conveyors in combination with product-carrying pallets you have the option to change the direction of the direction of products on the conveyor, and even stop and lift items as they move along the line.

Contact mk North America

If you’re searching for a solution for your application, roller chain or accumulation roller chain conveyors might be the right fit. Regardless of what you’re looking for, mk North America has an extensive catalog of options, for any industry. Contact us today!