Manufacturing Inefficiencies Solved with Conveyors

Posted on

Conveyors are a key element in improving efficiency in manufacturing. Here are some common inefficiencies that can be mitigated by implementing conveyor systems – lets look at the problem and the conveyor solution.

- Manual Handling:

- Problem: Manual handling of material or product can be slow, labor-intensive, and prone to errors.

- Solution: Conveyors automate the movement of materials and products, reducing the need for manual labor which in-turn minimizes the risk of errors and injuries.

- Inconsistent Production Flow:

- Problem: Variability in the pace at which materials and products that are moved can lead to bottlenecks and delays. These issues can be caused by a variety of external factors.

- Solution: Conveyors provide a consistent and predictable flow of materials, ensuring smooth production processes.

- Space:

- Problem: Poor layout and inefficient use of space can lead to congestion and wasted floor space. Not to mention, space is at a premium in nearly every production and manufacturing facility.

- Solution: Conveyors can be designed to optimize space usage, including vertical and horizontal transportation, thus freeing up valuable floor space. Conveyors can also be designed to go around structural hurdles, such as beams, poles and doorways. Additionally, certain conveyors can be used to simply accumulate a large volume of product.

- Downtime:

- Problem: Frequent stoppages for maintenance or to move materials manually can disrupt production.

- Solution: Modern conveyors are designed for reliability and ease of maintenance, reducing downtime and ensuring continuous operation. Combined with a preventative maintenance schedule; today’s conveyors are built to last.

- Quality Control Issues:

- Problem: Manual material handling can lead to inconsistent quality and damage to materials.

- Solution: Conveyors ensure gentle and consistent handling of materials, reducing the risk of damage and maintaining product quality. Depending on the specific requirements of the product, it is even possible to have a conveyor that doesn’t allow products to touch each other.

- Inventory Management:

- Problem: Inefficient movement and tracking of materials can lead to inventory mismanagement and stockouts. This is common when parts are left on carts, and carts are not accounted for.

- Solution: Automated conveyors can be integrated with inventory management systems to provide real-time tracking and efficient movement of materials. Parts, especially those which are assembled on the conveyor, can be moved via a pallet which can feature an RFID tag or other modern inventory control features.

- Labor Costs:

- Problem: High labor costs due to the need for manual transportation of materials.

- Solution: By automating material handling, conveyors reduce the reliance on manual labor, thus lowering labor costs.

- Ergonomic Issues:

- Problem: Manual handling of heavy or awkward materials can lead to ergonomic problems and worker injuries.

- Solution: Conveyors reduce the need for manual handling, improving workplace ergonomics and reducing the risk of injury. This is very similar and highly related to item seven on this list.

- Cycle Time:

- Problem: Delays in moving materials between workstations can increase the overall production cycle time.

- Solution: Conveyors speed up the movement of materials, reducing the cycle time and increasing throughput. Conveyors are also reliable, which means operators or robots can be in pace with the material flow.

- Waste and Scrap Reduction:

- Problem: Inefficient handling and transportation can result in material waste and scrap; due to inefficiencies in material handling and damaged parts.

- Solution: Conveyors provide precise and controlled movement, reducing the likelihood of waste and scrap – simply due to their reliable nature and ability to handle parts repeatedly and accurately.

By addressing these inefficiencies, conveyors can significantly enhance productivity, reduce costs, and improve overall manufacturing efficiency.

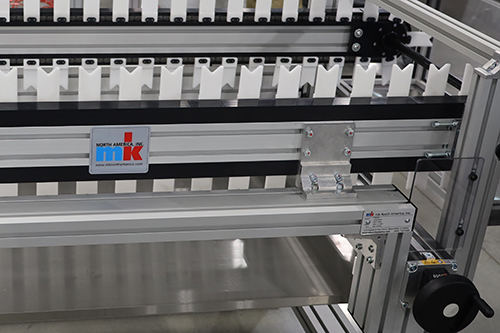

If you are interested in learning more about how conveyors from mk North America can benefit your operator complete the form below or call us at (860) 769-5500.