Custom Conveyors Explained

Posted on

What makes a conveyor system custom?

Is it the ability to select a specific length or width or both?

Is it being able to have a belt that can withstand extreme temperatures?

Is it a conveyor that can justify the product, carry it over a gap, and aide in visual inspection?

Yes! Yes! and Yes!

Custom conveyors are all these things and so much more. Continue reading to learn all about custom conveyor solutions.

What makes a conveyor system custom?

Custom Conveyors: Minor Modifications

How minor a modification, on a conveyor, is really depends on the conveyor manufacturer you are working with. Some conveyor manufacturers would consider a specific length to be a modification. Others may consider being able to select your belt or roller type for the conveyor be a modification. But at mk North America, we believe the customer should have the option to choose the conveyor length (down to the millimeter in some cases), the belt or roller type, the location of the drive, and the conveyor height – we could go on and on.

At mk we offer the widest range of standard drives, idlers, supports, rails, lengths, widths, heights, and conveyor types in the industry. This means more-often-than-not a conveyor that would be custom from another manufacturer is standard from mk. This means shorter lead-times and competitive pricing.

At mk North America, the items we'd consider to be minor modifications or customizations include the following:

- Easy to use locking handles for stand or rail adjustments.

- End stops.

- Upgrades in belting or motor types for specific environments.

- Bump turns for guiding products around corners or changing orientation.

Custom Conveyors: Major Modifications

There are times when a minor modification simply will not do, and a major modification is required. This can be done for any number of reasons, such as ensuring a conveyor can be used in an explosive environment. These modifications typically involve multiple conveyor components and are often not solely limited to add-ons to the conveyors.

Major conveyor modifications is the most encompassing of custom conveyor types, as it covers everything that is not a "simple" conveyor modification but not a truly custom conveyor. And what is considered a custom conveyor with major modifications varies greatly from conveyor manufacturer to conveyor manufacturer. This will depend greatly on the conveyor manufacturer’s standard offering and what supporting products they offer, such as linear motion modules and t-slot aluminum framing.

Some of the major conveyor modifications that mk is asked to provide in the past, or are deemed necessary by our design engineers based on the customer’s specific application include:

- Extremely tight nose-bars (down to 3 mm).

- Conveyors with workstations built onto the conveyor frame.

- Product nests – either mounted to the conveyor belt or as an end stop.

- Product locators for justifying products.

- Sweepers to move product or totes between conveyors.

- Conveyors with safety guards built around them.

- Custom belt guiding mechanisms.

- Conveyors with custom drive roller diameters or materials.

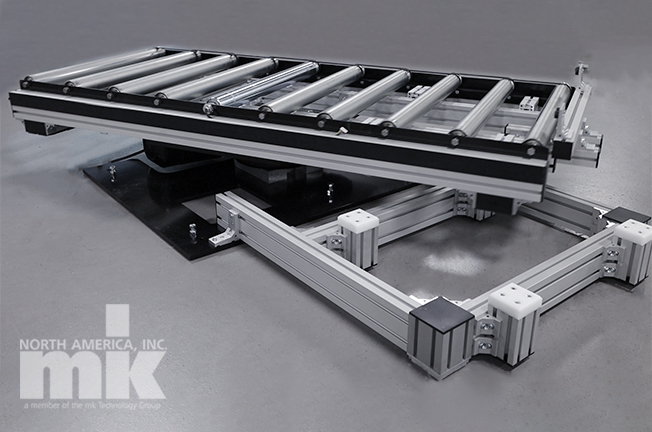

- Conveyors with elaborate supports for sliding conveyors into position.

- Adjustable lane spacing on multi-lane conveyors.

So, if all of these examples are major modifications then what is a truly custom conveyor?

Custom Conveyors: One-of-a-Kind

At mk North America we consider custom conveyors to be one-of-a kind and not something you would find as part of our standard conveyor product offering. Some conveyor manufacturers consider conveyors built to a customer’s exact length to be one-of-a-kind, but not mk.

mk’s custom conveyors are typically designed to solve very specific and unique challenges facing a customer. Our team of sales professionals works with the customer and our engineers to ensure the application is completely understood – from product being conveyed to the end goal. This helps ensure that the customer conveyor delivered meets and exceeds the customer’s expectations.

Some examples of custom conveyors we have built include:

- Conveyor systems for holding bullet proof vests for x-raying on the battlefield.

- Extremely wide and short conveyors with tight nose bars and true belt tracking.

- Back-lit conveyors with specific color light panels or multiple light panels .

- Conveyors with flat stainless-steel belts or mesh steel belting.

- Side gripper conveyors for conveying product of varying widths over gaps.

- Vertical conveyors – bucket style or with cleats.

- Brush conveyors for glass handling.

- Bi-Flow conveyors for either random product storage or LIFO/FIFO applications.

Getting Started with a New Conveyor Applications

When you are ready to get started on a new conveyor application take a confident first step and reach out to a conveyor manufacturer, like mk North America. A company that will take the time to listen to and understand your application and then make a recommendation on the best possible conveyor solution – no matter if it’s a standard or custom offering.

If you are ready to get started today – simply fill out the form below and a member of our team will be in touch!