Carousel Conveyors - Endless Options for Conveying

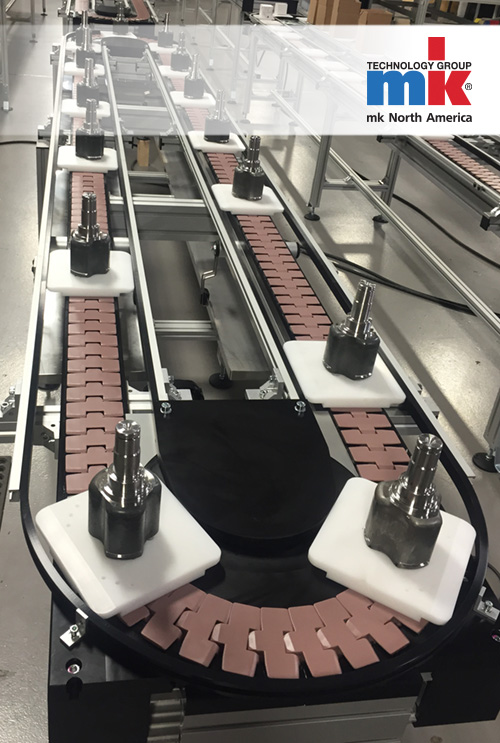

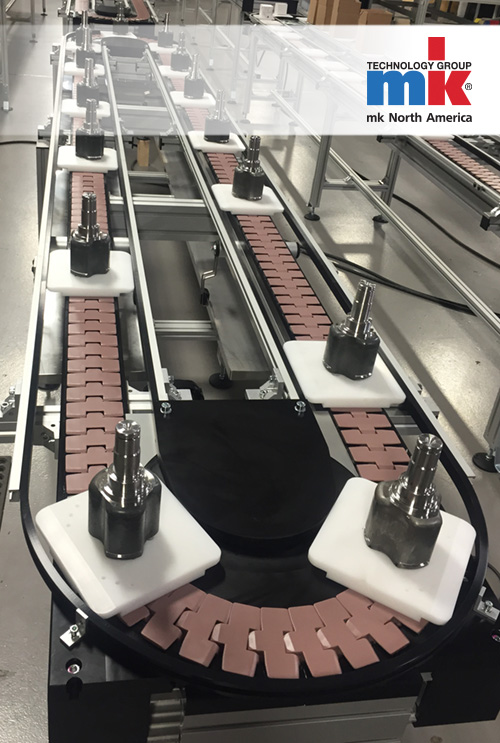

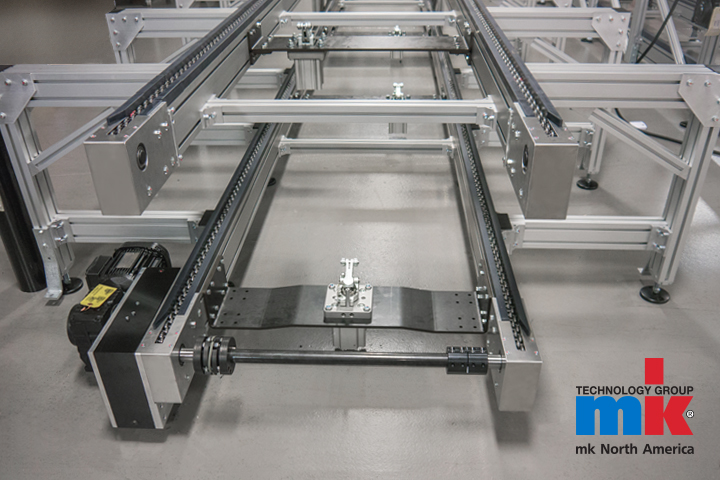

The SRT-P 2005 conveyor from mk North America combines the advantages of a table top chain conveyor with the performance of a pallet handling conveyor system.

The SRT-P 2005 conveyor from mk North America combines the advantages of a table top chain conveyor with the performance of a pallet handling conveyor system.

Staying competitive in manufacturing is a difficult task these days. Costs are rising and margins are narrowing, all while demands for innovation in research and development increases across industries.

While some of the challenges inherent to modern manufacturing simply have to be lived with, there are some areas where manufacturers have a great deal of control. Among the most significant is in optimizing assembly production.

When one factors in labor, time, and other resources, assembly accounts for as much as three-quarters of total manufacturing costs for any given product. By making sure assembly production is optimized, manufacturers can make considerable gains in improving overall efficiency and lowering costs. But as with most things, this can be easier said than done.

Since the 1960s, the automotive manufacturing industry has been at the forefront of industrial robotics and automation. In fact, the first industrial robot in history, George Devol’s Unimate, worked welding die castings to auto bodies for a General Motors assembly line starting way back in 1961!

With the International Federation of Robots estimating that the automotive industry will account for at least half of the worldwide growth in the robotics industry through 2018, it doesn’t look like the relationship between robots and car companies is changing any time soon.

They say a picture is worth a thousand words.

Then how many words is a video worth?

Just a few weeks ago mk North America released four new videos about their VersaMove pallet conveyor line.

Never heard of a pallet conveyor before? This first video highlights the various pallet conveyor platforms from mk, as well as showcasing some of the possible uses.

As industrial demand for reduced overhead costs and increased efficiency grows, so too does the demand for manufacturing process and factory automation. Factory automation helps manufacturers to increase production rates, material efficiency, worker safety, flexibility, and more, all while bringing down overall costs.

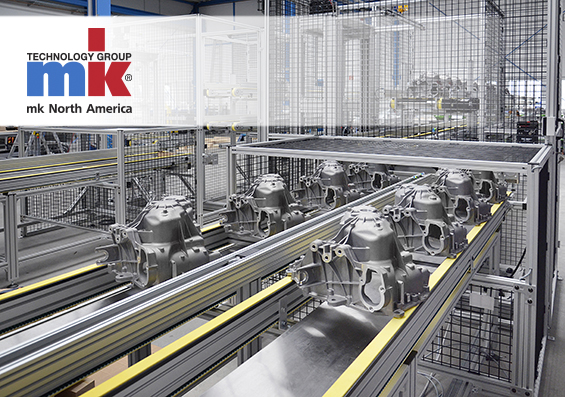

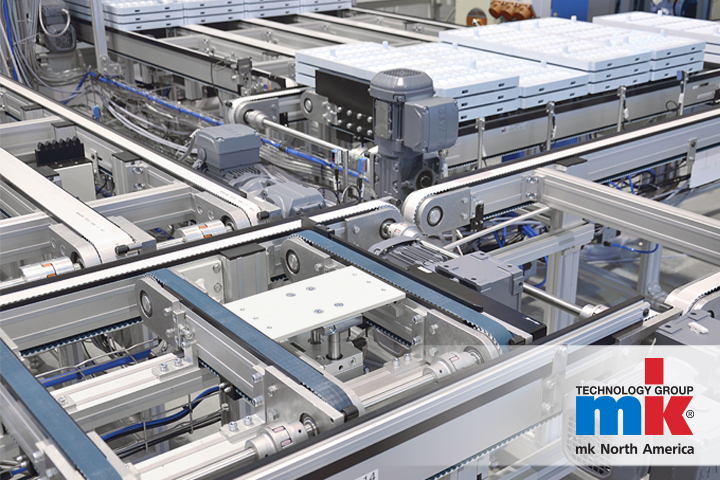

For almost any industrial process, conveyors are one of the most crucial components of a comprehensive factory automation system. mk North America is a leader in industrial automation, providing modular pallet conveyor systems, belt conveyors, sanitary conveyors, and more including custom conveyor design to meet specific demands.

Created using our VersaMove pallet conveyor systems, over under conveyors from mk North America consist of two or more conveyor lines stacked on top of each other. Pallets move between each level with an elevator or vertical transfer unit on each end. This configuration allows human or robotic operators to work on upper conveyor lines while empty pallets recirculate on lower levels. However, the VersaMove system is completely modular and custom configurations can be easily created to meet your specific needs.