Webinar: Modern Conveyor for Tomorrow's Automation

In April 2022, mk North America, in partnership with Design World a WTWH Media company, hosted a webinar on "Modern Conveyors for Tomorrow's Automation".

In April 2022, mk North America, in partnership with Design World a WTWH Media company, hosted a webinar on "Modern Conveyors for Tomorrow's Automation".

Back in 2016, we looked at over under conveyor systems using mk belt and high-load conveyors. But times have changed, and new technologies have been developed. In this article, we’ll explore two of these newer conveyor types, learn their differences and similarities and see how they stack-up against more traditional over under conveyor models.

In a previous post, we explored various product characteristics and how they affect conveyor selection type. One of the specific questions asked was “Does the product have a leading edge that should be maintained during conveying?” In this post we’re going to dive deeper into that question and unpack what the leading edge is and how to maintain it.

Conveyors come in many different styles and configurations and they move product from place to place. Conveyors can move it on a belt, chain or roller, to name a few. They can also move product horizontally, up inclines, and vertically. Conveyors can be reciprocating or move product around corners as well. But did you also know that conveyors are responsible for HOW product is delivered? Continue reading to learn about the three main modes of conveyor operation.

This is a copy of the original press release which first appeared on ABNewswire July 13, 2021.

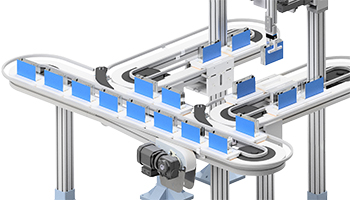

The newest addition to mk North America’s line of pallet conveyors, the VersaFlex P08, is a small, flexible chain pallet-handling conveyor system that carries loads up to 22 pounds per pallet and can be easily altered to adapt to product changes.

One of the single biggest influences on conveyor design is the product being conveyed. In this post we’ve broken down the top five product characteristics to keep in mind when selecting a conveyor type.