Benefits of Closed Sided Extruded Aluminum for Laboratories

Posted on

Biomedical and pharmaceutical facilities are under pressure to maintain compliance in their workplaces while also increasing efficiency and maximizing output. Due to the potential for hazardous conditions, these facilities must work to maintain controlled, clean and fluid environments. To be set-up for success, they require workstations and equipment built with quality and safety in mind.

In these industries, t-slot extruded aluminum is a perfect choice because the material is lightweight – so it’s easy to move and build with. This option helps laboratories to remain compliant and reduce costs due to the lower cost of aluminum over stainless steel and with the t-slot in the aluminum, there is no welding or grinding required.

Here’s a closer look at why constructing your laboratory equipment with t-slot extruded aluminum material makes sense and how mk North America can help.

Closed Sided Extruded Aluminum Benefits

With closed sided (or flat finished) extruded aluminum offered by mk North America, the closed side of the extrusion offers a flat finish. The flat finish makes it easier to wipe down and to clean the equipment constructed out of it. That means there’s fewer chances for matter getting caught in the t-slot when compared to traditional extruded aluminum and it also gives the profile a completed appearance while increasing safety as it eliminates the possibility of something getting caught or someone touching the open spaces.

Some t-slots are necessary in the extruded aluminum in order to make it easy to build with and modular. Using t-slot covers to close these crevices can help prevent dirt, dust and other contaminants from building up.

In the life sciences field, and with laboratory conditions, cleanliness standards are high, however, having a lightweight and versatile option for building workstations in these environments is also important.

Choose mk North America

Aluminum framing from mk North America offers a modular approach to workstation, cart, and laboratory equipment. These items can be custom tailored to fit your laboratory needs, while offering a light weight, easy-to-move, strong and durable solution – all while providing the cleanliness factor and cohesive look required in these specialized environments.

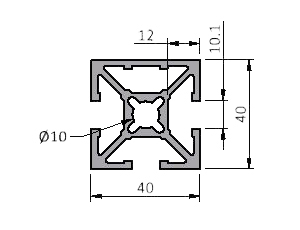

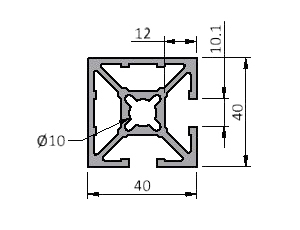

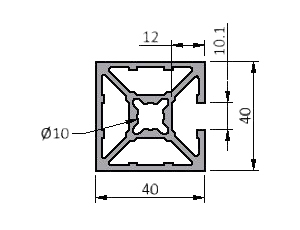

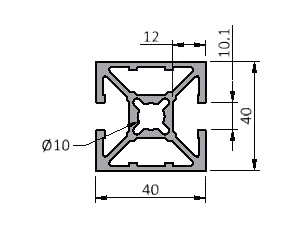

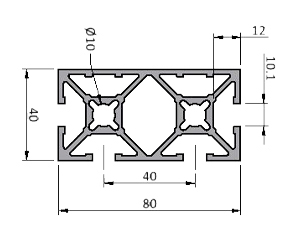

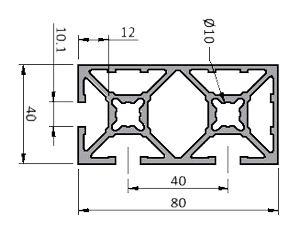

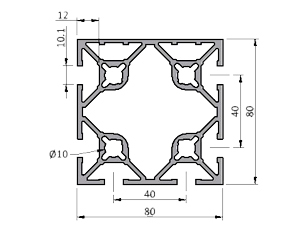

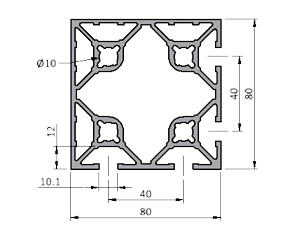

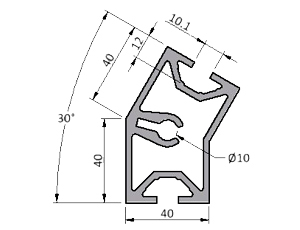

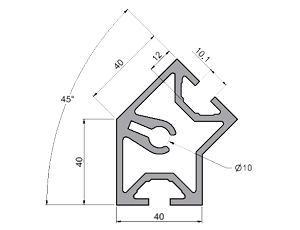

Our profile 40 series, and in particular the 54.200 series, offer a large selection of profiles, connectors and system components for framing applications, carts, and more. These are ideal for clean room applications and work well in areas where space constraints are present – such as small laboratories or separate rooms within the facility.

If you’re looking for a workstation surface, we offer several material options to choose from. A popular choice for laboratories is composite plastic - a resin that is corrosion and acid resistant and used for tabletop surfaces. We assemble your design request and ship it to you complete.

Examples of Various Profile Shapes Available

Additional profile shapes and combinations of closed sides are available.

Get in touch today!