AS, ESD & HC Conveyors

Posted on

AS, ESD and HC. Just throwing around letters? No. Those are all electrical abbreviations that apply to conveyor belting and in some cases to the conveyor as a whole. Let’s look into these terms, and the conveying applications where they may be used.

Anti-Static Conveyor Belts and Conveyors

If you haven’t already guessed it, AS stands for anti-static. So, what does anti-static (or antistatic) mean? According to the Oxford dictionary it is an adjective meaning: preventing the buildup of static electricity or reducing its effects. In the case of antistatic conveyor belts, they are designed to provide electrical resistance to that buildup of static electricity.

Different belt manufacturers make their belts differently, this is also true for anti-static belts. However, the most common way to construct these belts requires that an electrically conductive antistatic agent be imbedded into the belt. Some manufacturers may choose to coat their belt with this agent, however, in order to ensure long and reliable belt life mk North America typically does not use these belts on their antistatic conveyors. For added confidence in the belts antistatic capabilities be sure to ask what the belt’s antistatic resistivity is. Some of mk’s belt suppliers have belts that measure at less than 1010 ohms/squared (1010 Ω/sq.) while others are measured to different standards (ISO 21178) lengthways is parallel to the surface of the belt RDi < 3 x 108 Ω.

Static Build-up as a Concern in Manufacturing

But how can a conveyor have a build up of static electricity? Static electricity is generated in a conveyor between the underside of the conveyor belt and the dead plate on the conveyor due to the constant motion of the belt on the plate – very similar to rubbing a balloon on your hair and watching you hair stand on end. These belts can also be used to address the issue of static discharge between the product and the top surface of the belt. Static discharge can also attract dust and other minute particles, it can ignite flammable items, it can destroy sensitive electrical components and in some cases even disturb the line operators.

Industries that Are Concerned About Static Electricity in Conveyor Belting

Some of the industries that are concerned about the static electricity build up on a conveyor can seem obvious based on what we discussed in the paragraph before.

- Airports

- Automotive

- Aviation

- Cleanroom

- Converting

- Electrical and Electronic Device Manufacturing

- Flat Screen Manufacturing

- Food Industries

- Medical Device Manufacturing

- Sugar Processing

- Packaging, Order Fulfillment and Logistics

- Plastics

- Printing and Painting

ESD or Electro-Static Dissipative Belts

It seems like there is a lot an AS belt can do, so why do we also need ESD belts? Simply put, ESD belts offer more static discharge capabilities than an anti-static belt. Similar to the different ohm rating we saw with antistatic belts, ESD belts from different manufacturers will have different ohm ratings as well.

Some conveyor belt manufacturers, such as Forbo-Siegling, even offer a Highly Conductive (HC) belt which is one of the highest rated electrostatic dissipative belts on the market.

In the end, the question of “why do we also need ESD belts” comes down to the application requirements. And working with a conveyor company, such as mk North America, who has relationships with a variety of belt manufacturers can help ensure the belt selected for your application is the belt needed for your application.

Beyond the Conveyor Belt

Many applications also require the conveyor to also be grounded, in order to give the static electricity some place to go. Conveyor can be equipped with devices that provide an “outlet” for the static electricity, but the location in which the conveyor is going also needs to be prepped to provide the grounding mate or anchor. For operators that work on conveyor lines in sensitive areas they may be required to wear grounding wrist bands and/or have workstations that are equipped with anti-static mats that are also grounded.

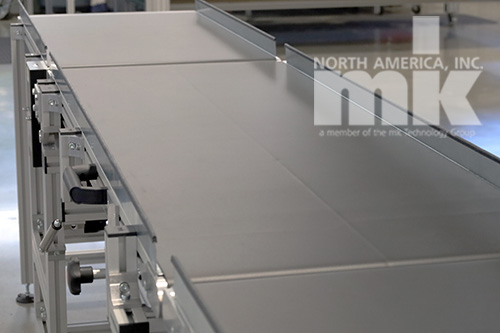

AS, ESD and HC Conveyors from mk

mk’s line of belt conveyors, particularly the GUF-P 2000 and GUF-P 2041, can easily be outfitted is AS, ESD or HC belts and grounding devices. Our chain conveyors, which feature steel chains, can be built using anti-static wear strips (the channel in which the chain rides). Timing belt conveyors can be built using similar antistatic wear strips, and the timing belts themselves can be coated (topside, tooth side, or both) in an antistatic coating. If you are ready to learn more or want to get started on a project fill out the form below or call us at (860) 769-5500 and we will be happy to assist you.