An Engineer’s Guide to Actuators: Types, Applications, and Selection Criteria

Posted on by David Johnson, Engineering Manager, Aluminum Conveyors and Factory Automation

In the rapidly evolving world of industrial automation and mechanical design, actuators are a crucial component responsible for creating controlled motion. Whether you are designing a conveyor system, integrating automated machinery, or optimizing manufacturing processes, understanding the different types of actuators and their applications is essential for selecting the right component.

At mk North America, we specialize in providing high-quality conveyor solutions that often integrate various actuators for material handling, positioning, and motion control. This guide will give you a comprehensive understanding of actuators, their types, and the key factors to consider when choosing one for your application.

What is an Actuator?

An actuator is a mechanical device that converts energy into motion. The energy source can be electrical, pneumatic, hydraulic, thermal, magnetic, or piezoelectric, and the resulting motion can be either linear or rotary. Actuators are essential in industrial automation as they provide controlled movement in applications such as conveyors, pick-and-place systems, and adjustable platforms.

Linear vs. Rotary Actuators

Linear actuators generate motion along a straight line. They are commonly used in applications that require pushing, pulling, lifting, lowering, or positioning an object. A linear actuator typically consists of a motor coupled with a mechanism like a ball screw, rack and pinion, or belt and pulley. In conveyor systems, linear actuators are often used to automate product diverting, stopping, or indexing.

Rotary actuators, on the other hand, provide rotational motion. They are ideal for applications that require rotating parts, such as turning, clamping, mixing, or valve control. While rotary actuators offer higher torque, they typically operate at lower speeds than linear actuators.

At mk North America, our conveyor systems can integrate both linear and rotary actuators depending on the needs of your material handling process.

Types of Actuators

Electric Actuators

Electric actuators are powered by electricity and typically use DC motors, stepper motors, or servo motors to generate motion. These actuators offer high precision, excellent control, and low maintenance requirements. They are often used in conveyor systems where accuracy in product placement is critical.

Advantages: |

Disadvantages: |

|

|

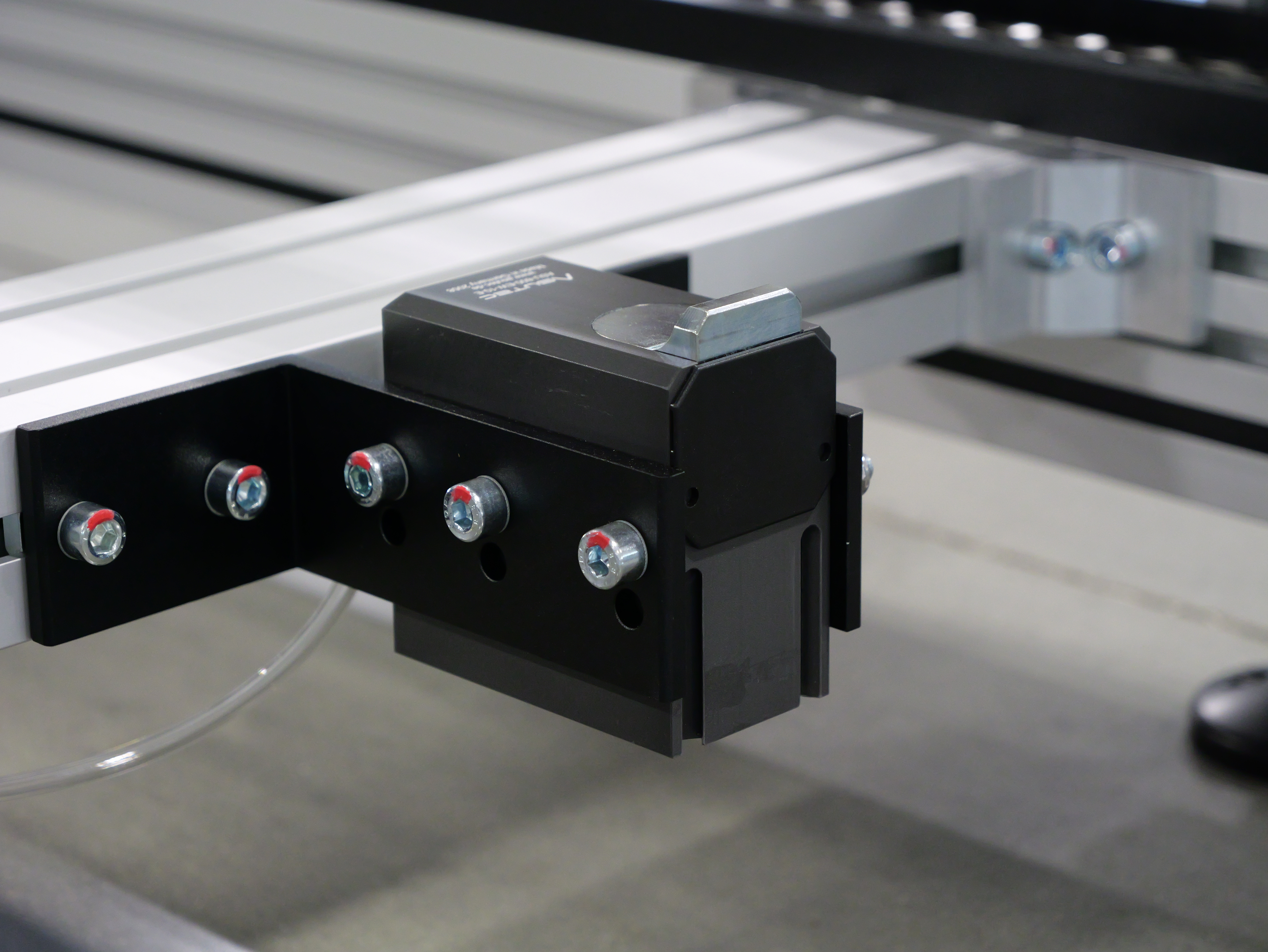

mk North America Solution: We offer electric linear actuators as part of our conveyor accessories, ideal for applications that require precise indexing, stopping, or diverting.

Pneumatic Actuators

Pneumatic actuators use compressed air to generate motion. They are commonly found in fast-moving automation environments, such as packaging lines or assembly lines, where speed and repeatability are paramount.

Advantages: |

Disadvantages: |

|

|

mk North America Solution: Pneumatic actuators can be integrated into our conveyor diverters, pushers, and transfer units to provide rapid motion control in high-speed packaging or assembly environments.

Choosing the Right Actuator for Your Conveyor System

When selecting an actuator for your conveyor system, several factors should influence your decision:

- Load Capacity - Determine the maximum load the actuator will need to handle. For high-load applications, electric actuators are recommended.

- Speed and Precision - For high-speed applications, pneumatic actuators may be ideal. However, for precise and controlled movements, electric actuators are preferred.

- Space Constraints - Evaluate how much space you have for the actuator installation. Compact linear actuators may be better suited for limited-space environments.

- Energy Efficiency- Energy consumption is another critical factor. Electric actuators are typically more energy-efficient, while pneumatic actuators may consume more energy over time.

- Integration with Control Systems - Consider whether the actuator needs to integrate with a PLC or automation system. Electric actuators offer seamless integration for precise motion control.

How mk North America Integrates Actuators in Conveyor Systems

At mk North America, we understand that selecting the right actuator is critical for ensuring maximum performance and efficiency in material handling systems. Our conveyor solutions can integrate electric or pneumatic actuators depending on your specific application needs.

Popular Applications:

- Indexing Conveyors: Electric actuators provide precise stop-and-go motion for product positioning.

- Product Diverting: Pneumatic actuators are commonly used in diverters or lane change systems for high-speed sorting.

- Lifting or Lowering: Hydraulic actuators can be integrated into heavy-duty lifting tables for material positioning.

By working with mk North America, you gain access to custom conveyor solutions that incorporate the most efficient actuator technologies to meet your production needs.

Understanding the role of actuators in industrial automation is key to designing efficient and reliable conveyor systems. Whether you need fast, high-force, or precision movement, choosing the right actuator type can significantly impact your system's performance. At mk North America, we are committed to delivering cutting-edge conveyor solutions that integrate the best actuator technology to optimize your production efficiency.

For more information or to discuss your specific application needs, contact your regional sales manager and let our engineering team design a custom solution for you.